Plastic Injection Molding Manufacturer

As a professional China plastic injection molding manufacturer, we provide high-quality plastic part manufacturing services for different industries.

Featured Injection Molding Process

Recent Injection Molding Solutions

Why 500+ Customers Choose Us

China Injection Molding Supplier FAQ

What Our Clients Say Us

Our Promise

- A very competitive price to help you cut costs and increase profits or improve your market competitiveness.

- From drawings to prototypes, then be economical injection molded parts, we provide a one-stop service to make your unique idea be the reality.

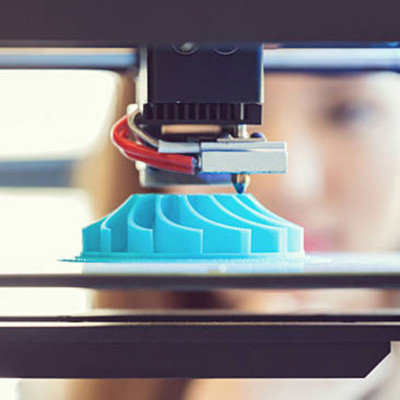

- With our plastic rapid prototyping, you can test your business ideas before your final decision.

- No matter how complicated the part, how the order quantity you need, Holly will bring your product to market.

As part of our development of a new sampling device, we needed to test multiple prototype parts – from hardware-software integration and ergonomics of handheld operation, through to snap strength verification for housing snaps. Holly Plastics provided us with a full set of functional prototypes using 3D printing and vacuum casting in only five days, all to an outstanding standard with appearances closely matching those found in mass-produced parts, hardness, dimensions all being within tolerances. Jackie consistently understood our design intent quickly and provided improvement suggestions based on our feedback after each validation round. In total, four iterations rounds were completed by Holly on this project – both their rapid prototyping ability and smooth communication are reasons we continue to entrust them with our work.

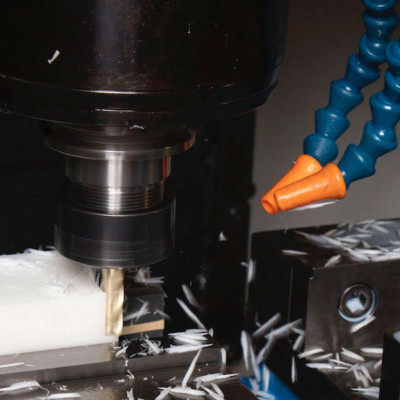

Holly Plastics stood out among three evaluated suppliers by manufacturing aluminum CNC prototype parts that met our design tolerance of +-0.02mm with excellent anodized surface finish that had no burrs or scratches, even with only basic requirements provided to Jackie’s engineering team. Jackie quickly filled in all necessary manufacturability details without needing multiple revisions back and forth; one standout feature was their prompt turnaround – we required test parts within 4 days and received them three days early- perfect timing! For an R&D team like ours where timing is critical, Holly Plastics proved itself as an indispensable partner!

Over the last three years, Holly Plastics and I have successfully created three wearable products together. From initial 3D printed functional prototypes and CNC-machined housings for strength validation to small batch vacuum cast testing and injection mold design and mass production, they have provided professional and reliable support at every stage. On a recent occasion, we needed 10 high-quality display units quickly for an international trade show. Jackie took it upon herself to expedite this process and ship all 10 units within two days–resolving an important issue with just enough time left before its deadline. Working alongside Holly made clear they don’t just complete orders–they genuinely think from customer perspective and find solutions.